IMARC Group has recently released a new research study titled “United States Aerospace Composites Market Report by Fiber Type (Carbon Fiber Composites, Ceramic Fiber Composites, Glass Fiber Composites, and Others), Resin Type (Epoxy, Phenolic, Polyester, Polyimides, Thermoplastics, Ceramic and Metal Matrix, and Others), Aircraft Type (Commercial Aircraft, Business Aviation, Civil Helicopters, Military Aircraft and Helicopters, and Others), Application (Interior Parts, Exterior Parts), Manufacturing Process (AFP/ATL, Layup, RTM/VARTM, Filament Winding, and Others), and Region 2025-2033,” which offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends, and competitive landscape to understand the current and future market scenarios.

United States Aerospace Composites Market Overview

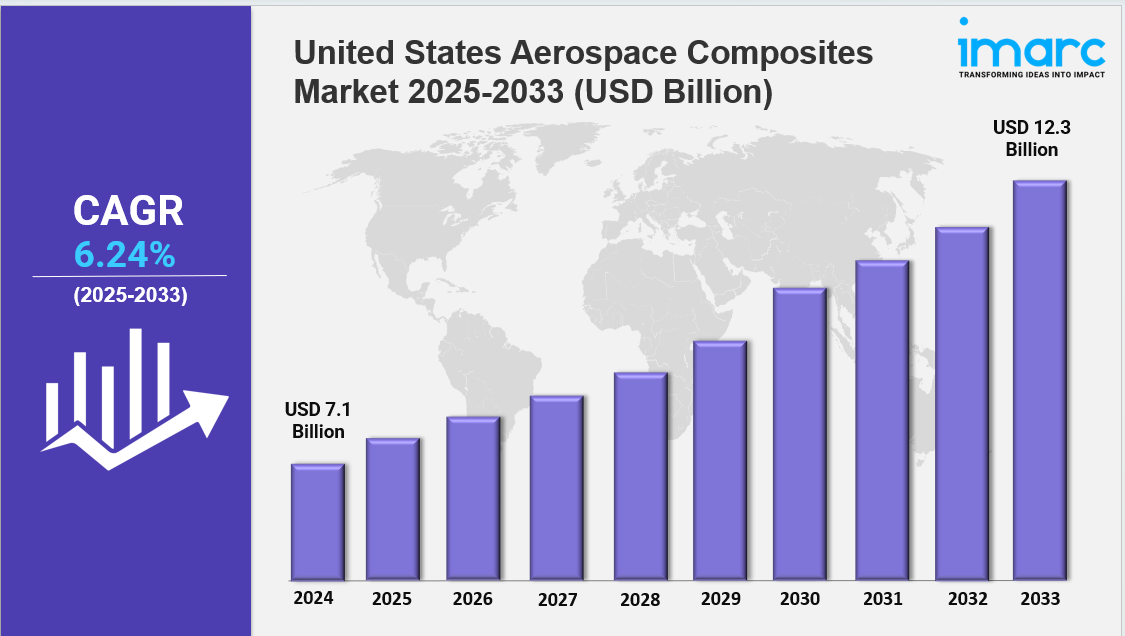

The United States aerospace composites market size reached USD 7.1 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 12.3 Billion by 2033, exhibiting a growth rate (CAGR) of 6.24% during 2025-2033.

Market Size and Growth

Base Year: 2024

Forecast Years: 2025-2033

Historical Years: 2019-2024

Market Size in 2024: USD 7.1 Billion

Market Forecast in 2033: USD 12.3 Billion

Market Growth Rate 2025-2033: 6.24%

Request for a sample copy of the report: https://www.imarcgroup.com/united-states-aerospace-composites-market/requestsample

Key Market Highlights:

✔️ Strong market growth driven by rising aircraft production and lightweight material demand

✔️ Increasing adoption of carbon-fiber composites for fuel efficiency and performance

✔️ Expanding applications in defense, commercial aviation, and space exploration sectors

United States Aerospace Composites Market Trends

The United States Aerospace Composites Market is growing steadily. The aerospace industry needs lightweight materials to boost fuel efficiency and cut emissions. Airlines and manufacturers face pressure to follow strict environmental rules while reducing costs. As a result, composite materials are key in modern aircraft design.

They have a high strength-to-weight ratio and are used in fuselages, wings, and tail sections for both commercial and military aircraft. These materials help support longer flight ranges and better fuel economy. Also, the move toward sustainable aviation is increasing demand. Composites allow for more aerodynamic and eco-friendly aircraft structures.This strong momentum is contributing significantly to United States Aerospace Composites Market Growth.

The United States Aerospace Composites Market Size is growing. Manufacturers are investing more in research and development. They aim to create advanced materials and boost production efficiency. Demand comes from the commercial aviation sector, military modernization programs, and the need for greener aircraft. Composites are now essential in the industry. Increasing passenger traffic and aircraft replacement cycles also support market growth. This strengthens the long-term outlook.

Technological Advancements Driving Growth

Technological innovation remains a core driver of United States Aerospace Composites Market Growth. Advanced manufacturing processes such as automated fiber placement (AFP) and resin transfer molding (RTM) are enhancing precision, reducing material waste, and lowering production costs.

The adoption of additive manufacturing (3D printing) is also revolutionizing aerospace composites, enabling faster prototyping and customized component production. These innovations are paving the way for next-generation aircraft that are lighter, stronger, and more fuel-efficient, boosting the overall United States Aerospace Composites Market Share in the global aerospace industry.

Regulatory Compliance and Safety Standards

Strict regulations from the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) shape the United States Aerospace Composites Market. Compliance ensures materials and processes meet strict safety and performance standards. This regulatory landscape affects product development, testing, and certification. Manufacturers must prioritize quality assurance and risk management. Collaboration among regulatory agencies, manufacturers, and suppliers is key. It balances innovation with safety, ensuring the reliability of aerospace composites in critical applications.

Key Trends Shaping the Market

Several important trends are influencing the United States Aerospace Composites Market Outlook:

Sustainability and Eco-Friendly Materials: Manufacturers are developing bio-based composites and recycling programs to support environmental goals and reduce carbon emissions.

Digital Integration: The use of IoT and data analytics allows real-time monitoring of composite performance, predictive maintenance, and optimized supply chain management.

Modular Aircraft Design: Composites are enabling modular systems that make upgrades and maintenance easier, improving operational efficiency.

These trends reflect the aerospace industry’s commitment to innovation, sustainability, and long-term performance, further reinforcing the market’s competitive edge.

United States Aerospace Composites Market Outlook

The United States Aerospace Composites Market Size is set to grow. This growth comes from rising demand for fuel-efficient, lightweight, and sustainable aircraft. Increased investments in R&D and new production technologies will drive this trend. Also, expanding uses in commercial and defense aviation will support strong momentum. The U.S. holds a strong United States Aerospace Composites Market Share and remains a global leader in aerospace composites. It shapes the future of aviation with a focus on performance, innovation, and sustainability.

United States Aerospace Composites Market Segmentation:

The market report segments the market based on product type, distribution channel, and region:

Breakup by Fiber Type:

Carbon Fiber Composites

Ceramic Fiber Composites

Glass Fiber Composites

Others

Breakup by Resin Type:

Epoxy

Phenolic

Polyester

Polyimides

Thermoplastics

Ceramic and Metal Matrix

Others

Breakup by Aircraft Type:

Commercial Aircraft

Business Aviation

Civil Helicopters

Military Aircraft and Helicopters

Others

Breakup by Application:

Interior Parts

Exterior Parts

Breakup by Manufacturing Process:

AFP/ATL

Layup

RTM/VARTM

Filament Winding

Others

Breakup by Region:

Northeast

Midwest

South

West

Ask Analyst & Browse full report with TOC & List of Figures: https://www.imarcgroup.com/request?type=report&id=20646&flag=C

Competitive Landscape:

The market research report offers an in-depth analysis of the competitive landscape, covering market structure, key player positioning, top winning strategies, a competitive dashboard, and a company evaluation quadrant. Additionally, detailed profiles of all major companies are included.

Key Highlights of the Report

1. Market Performance (2019-2024)

2. Market Outlook (2025-2033)

3. COVID-19 Impact on the Market

4. Porter’s Five Forces Analysis

5. Strategic Recommendations

6. Historical, Current and Future Market Trends

7. Market Drivers and Success Factors

8. SWOT Analysis

9. Structure of the Market

10. Value Chain Analysis

11. Comprehensive Mapping of the Competitive Landscape

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91-120-433-0800

United States: +1 201971-6302

Write a comment ...